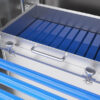

The MS25 Pneumatic Cuber reduces blocks of medium and soft cheese to clean cut cubes that create the best shred and dice appearance. The operator prepares cheese on the rollers in front of the cutting chamber, then pushes them into position. Once the cycle is initiated, the machine pushes the cheese up through the first stage, then over through the second stage cutting wires. The machine is capable of running blocks, wheels, and loose trim cuts. Interchangeable cutting harps are used to alter the cube size which ultimately changes the shred length. Cheese blends can be created by precutting blocks. An integrated metering conveyor mixes the cubes and delivers a continuous flow of cubes to the shredder or dicer.

- Quick change cutting harps

- Provisions for trim handling

- Dedicated PLC for independent controls

- Accumulation conveyor for continuous feed

- Easy clean conveyor separation